- Manufacturer Stockist & Supplier of : All Ferrous & Non Ferrous Metal

- Call us : +91 98927 02393

-

Email

Incoloy 825 Round Bars and Wires

Incoloy 825 Round Bars and Wires

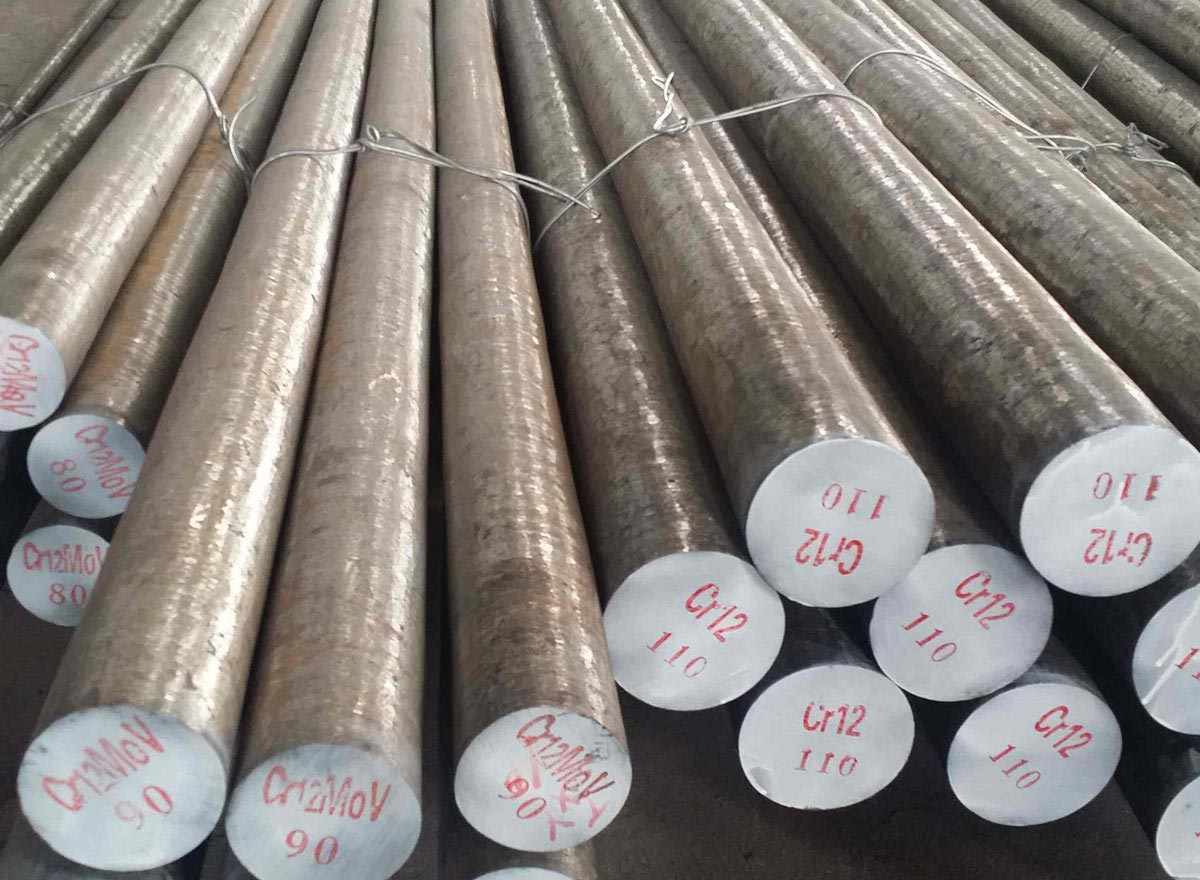

Incoloy Alloy 825 Cold Heading Wires Dealer in Mumbai, Incoloy 825 Flux Cored Wires Exporter, Incoloy Alloy 825 Bright Wires, Incoloy 825 Round Bars Suppliers, Incoloy 825 Round Bar and Wire, Incoloy 2.4858 Round Bars, ASTM B425 Incoloy 825 Welding Rod / Welding Wire Manufacturer, Incoloy 825 Bright Bar, Incoloy 825 Rectangular Bar Manufacturer in Mumbai.

Panache Industries is a renowned manufacturer and

supplier of

Incoloy 825 Round Bars & Wires. These are come to an application due to its

noticeable features such as excellent finish, robust

construction, and resistance to rusting, durability

and dimensional accuracy and many more. These are

manufactured from high-quality crude materials. We

represent them in various standards, specifications,

designations, shapes, and sizes. These are

manufactured by us in large quantities in our large

production facility, so customers can get bulk orders

from us.

Product description:

Incoloy 825 Round Bars & Wires

is composed of nickel, iron and chromium content. It

also has some amount of titanium, molybdenum and

copper content. It’s alloying elements and

chemical composition is formulated to provide

exceptional corrosion resistance even in exposed to

most corrosive environments. It is similar to its

original grade. It offers improved resistance to

reducing and oxidizing acids. These are also resistive

to sulfuric and phosphoric acids.

Alloy 825 is also known as UNS N08825 grade. It has

some amount of nickel makes it resistive to chloride

stress corrosion cracking. The combination of

molybdenum and copper derived its resistance ability

when compared to conventional grades.

Mechanical attributes:

It has good mechanical properties from cryogenic to down

temperatures. These are exposed to temperatures above 1000

degree F. this result in the change of microstructure that

is significantly lower ductile and has impact toughness.

These are utilized at temperatures where the creep rupture

properties are desired. These are strengthened by the cold

working process. It has high impact strength at room

temperatures while retaining its strength at hoists

temperatures.

It has an outstanding attribute of corrosion resistance.

These are utilized in both reducing and oxidizing

environments. These are also resistive to general,

crevice, local and pitting corrosion cracking. These serve

good performance in environments that contain a high level

of halides and chlorides.

Buy Comprehensive Variety of Incoloy Alloy UNS N08825 Welding Wire Manufacturer, ASTM B425 Incoloy Alloy 825 Filler Wires, Incoloy DIN 2.4858 Forged Round Bars Supplier, Incoloy 825 Round Bars Exporters, Incoloy 825 Round Bars Manufacturers, Incoloy 825 Round Bars Exporter, Incoloy Alloy 825 Rectangular Bar, Incoloy 825 Wire Rods Manufacturer in India.

Incoloy 825 Wires

Incoloy 825 Wire, Incoloy 825 Coarse Wires, Incoloy Alloy 825 Wires, Incoloy 825 Fine Wires, Incoloy 825 Round Bars Exporters, Incoloy Alloy 825 Filler Wires, Incoloy 825 Wire Rod, Incoloy 825 Round Wires Suppliers, Incoloy 825 Round Bars Suppliers, Incoloy DIN 2.4858 Welding Rod / Welding Wire, Incoloy 825 Flux Cored Wires, Incoloy 825 Wires Exporters, Incoloy 825 Spring Wire, Incoloy 825 Filler Wires.

Incoloy Alloy 825 Round Bars

825 Incoloy Round Bar, Incoloy Alloy 825 Threaded Bar, Incoloy Alloy 825 Round Bar and Rod, Incoloy Alloy 825 Forged Round Bar, Incoloy Alloy 825 Round Bars, Incoloy 825 Wires Manufacturers, Incoloy Alloy 825 Round Bars, Incoloy Alloy 825 Round Rod, Incoloy Alloy 825 Welding Rod, Incoloy Alloy UNS N08825 Bright Bar.

Certainty of Incoloy 825 Round Bars &

Wires:

The prepared lot is further proceeds for testing to

determine the functionality of products. The tests are

hardness test, tensile test, destructive

test/non-destructive test, positive material test,

intergranular corrosion test, ultrasonic test,

radiographic test, pitting corrosion test and more.

Incoloy 825 Round Bars Specifications

Specification : ASTM B425 / ASME SB425

Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI

Length : 100 mm To 3000 mm Long & Above

Size : 5 mm To 500 mm

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Surface : Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline

Condition : Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished

Incoloy 825 Wires Specifications

Specifications : ASTM B425 ASME SB425

Dimensions : ANSI/AWCI – 01 -1992 and ASTM E 2016-11 and RRW 360

Length : 100 mm TO 8250 mm

Diameter Range : 10 mm To 100 mm

Specialize : Filler Wire, Coil Wire

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | OR | BS | GOST | JIS |

| Incoloy 825 | N08825 | 2.4858 | NFE30C20DUM | NiCr21Mo | XH38BT | NA 16 | ЭП703 | NCF 825 |

| C | Al | Mn | Si | Ti | Ni | Fe | Mb | Cu | Cr | S |

| 0.05 max | 0.2 max | 1.0 max | 0.5 max | 0.6 – 1.2 | 38.0 – 46.0 | 22.0 min | 2.5 – 3.5 | 1.5 – 3.0 | 19.5 – 23.5 | 0.015 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.14 g/cm3 | 1400 °C (2550 °F) | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa –220 | 30 % |

Incoloy 825 Round Bars and Wires Application Industry

People Also Searched For Incoloy 825 Round Bars and Wires

incoloy 825 wire Dealers, incoloy uns N08825 round bar, incoloy 825 rectangular bar stockholder, incoloy alloy 825 wires manufacturers, incoloy 825 round wires suppliers, incoloy 825 rods suppliers, incoloy alloy 825 round rods, incoloy alloy 825 round bar and wire distributors, incoloy alloy 825 welding rod / welding wire manufacturers, incoloy alloy 825 square bar manufacturing process, incoloy 825 round bars suppliers, incoloy 825 round bars and wires manufacturers, incoloy 825 wire price per kg, incoloy uns N08825 filler wires, incoloy 825 wires manufacturers, incoloy 2.4858 round bar, incoloy 825 wire manufacturer in delhi, incoloy 825 round bars manufacturers, incoloy 825 square bar, incoloy 825 filler wire, A Wide Range Of the Best Quality incoloy alloy 825 forged round bars manufacturers in india, incoloy 825 wires exporters, incoloy 825 welding wire manufacturers in mumbai, incoloy alloy 825 cold finish round bar, incoloy 825 round bars exporters, incoloy 825 wires manufacturer in mumbai, incoloy 2.4858 wire bobbin, 825 incoloy Alloy bright bar.

Incoloy 825 Round Bars and Wires Packaging and Advantages

Types of Packaging:

– Bundles (hexagonal)

– Wooden Boxes

– Crates (steel/wooden)

– Packaging for Incoloy Alloy 825 Round Rod as per

customer’s requirements

Advantages :

– High Strength

– Resistant High Mechanical Stresses

– Resistant to High Temperature

– Good Formality

Incoloy 825 Round Bars Manufacturers | Incoloy Alloy 825 Wires Price | Incoloy 825 Round Rods distributors | ASTM B425 Incoloy Alloy Filler Wire | Incoloy Alloy 825 Forged Round Bar Ready Stock | Incoloy 2.4858 Cold Finish Round Bar Suppliers | Incoloy Welding Wire Stockist | Incoloy UNS N08825 Welding Rods Exporters | Incoloy 825 Round Bar and Wires Exporter

If you’re looking for a trusted and reliable supplier of Incoloy 825 Round Bar and Wires then contact Shop no. 8B, Jai Siddhivinayak CHS., Ardeshir Dadi X Street, Mumbai - 400 004, Maharashtra, India