- Manufacturer Stockist & Supplier of : All Ferrous & Non Ferrous Metal

- Call us : +91 98927 02393

-

Email

Incoloy 800/800H/800HT Round Bars and Wires

Incoloy 800/800H/800HT Round Bars and Wires

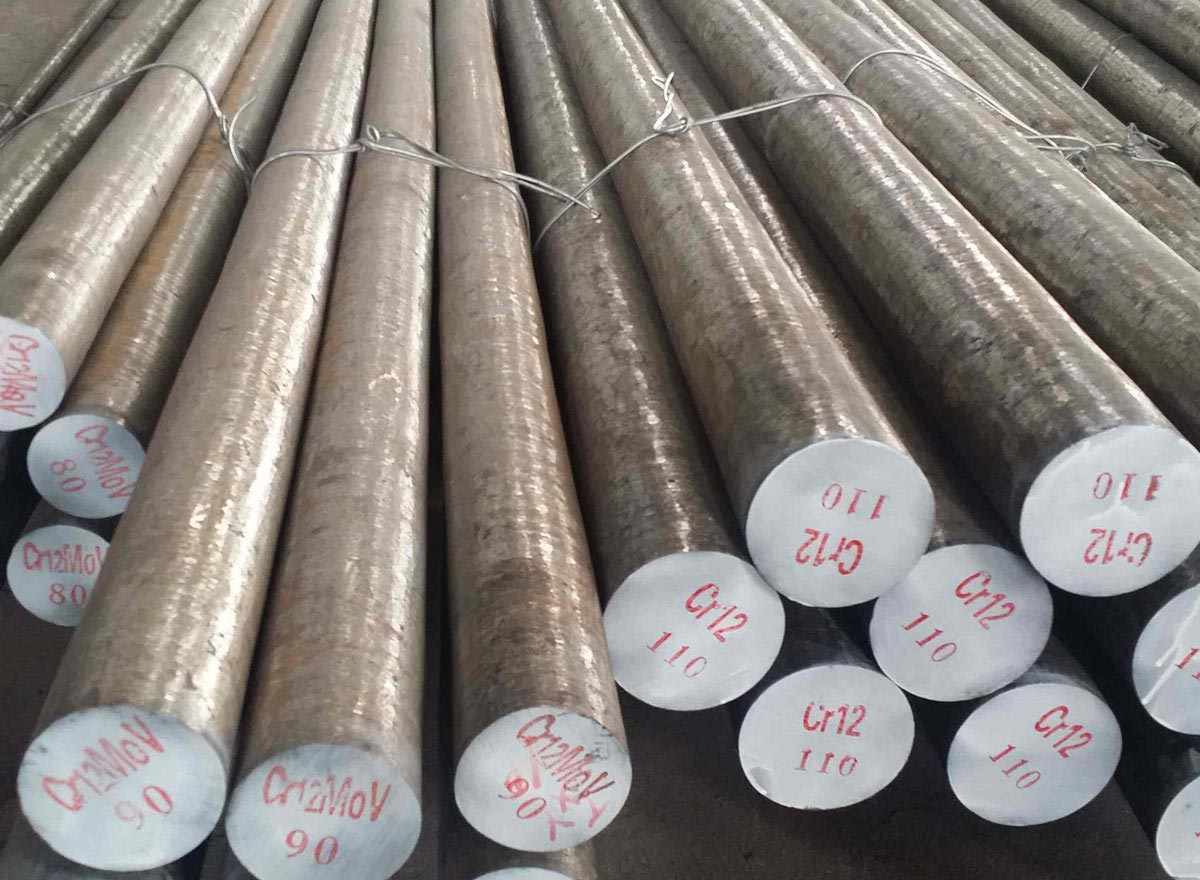

Buy Comprehensive Variety of Incoloy 800H Round Bars Exporter, Incoloy 800 Wire Rods, Incoloy DIN 1.4958 / 1.4876 Forged Round Bars Supplier, Incoloy Alloy UNS N08810 Welding Wire Manufacturer, Incoloy 800 Round Wires Suppliers, Incoloy 800 Round Bars Suppliers, ASTM B425 Incoloy Alloy 800 Filler Wires, Incoloy Alloy 800HT Rectangular Bar Manufacturer in India.

There are various manufacturers available that are providing their customer's wide variety of round bars and wires. But, when it comes about the quality product, you can undoubtedly trust Panache Industries. It is one of the leading manufacturing companies that manufactures and supplies high quality of Incoloy 800 / 800H / 800HT Round Bars & Wires. These are Incoloy products; therefore, their demand is quite high in the industrial market due to its features and mechanical properties it offers.

The round bars are provided to customers in varied shapes, sizes, and forms to their customers as per their needs and requirements. The round bars and wires are manufactured using high and premium quality of material that is well inspected and tested by the qualified professionals. Each and every material is well tested to ensure that the material is of high quality and will perform its best under the respective areas of working.

Grade details

Alloy 800 / 800H / 800HT are iron-chromium-nickel based alloys having good strength

and excellent resistance to carburization and oxidation at high-temperature

exposure. These nickel-based steel alloys are considered identical except for the

high amount of carbon in the alloy 800H/ 80HT. all these alloys have a different

percentage of carbon content.

Features of Incoloy 800 / 800H / 800HT Round Bars & Wires

Well, if we talk about the features of these round bars and wires, these products

exhibit various excellent features and properties which make it suitable for all

types’ application. The features include hardness, good weldability,

workability, formability, high tensile strength, and long service life. All these

services are offered by these round bars and wires that is why they are considered

best for all types of applications.

ASTM B425 Incoloy 625 Welding Rod / Welding Wire Manufacturer, Incoloy Alloy 625 Bright Wires, Incoloy Alloy 625 Cold Heading Wires Dealer in Mumbai, Incoloy 800 Round Bars Exporters, Incoloy 625 Bright Bar Exporter, Incoloy 625 Round Bar and Wire, Incoloy 625 Rectangular Bar, Incoloy 1.4876 Round Bars, Incoloy 625 Flux Cored Wires Manufacturer in Mumbai.

Incoloy 800/800H/800HT Wires

Incoloy 800 Wire, Incoloy 800H Spring Wire, Incoloy 800HT Coarse Wires, Incoloy 800/800H Fine Wires, Incoloy 800 Wires Manufacturers, Incoloy 800HT Flux Cored Wires, Incoloy 800 Wire Rod, Incoloy Alloy 800H Wires, Incoloy DIN 1.4859 / 1.4876 Welding Rod / Welding Wire, Incoloy Alloy 800HT Filler Wires, Incoloy 800H/800HT Filler Wires.

Incoloy 800/800H/800HT Round Bars

Incoloy UNS N08811 Bright Bar, Incoloy 800 Forged Round Bar, 800H Incoloy Round Bar, Incoloy Alloy 800HT Round Bars, Incoloy Alloy 800/800H Threaded Bar, Incoloy Alloy 800 Round Bars, Incoloy Alloy 800H Round Bar and Rod, Incoloy 800 Wires Exporters, Incoloy Alloy 800HT Welding Rod, Incoloy Alloy 800/800HT Round Rod.

Testing and packaging

There are different tests done in order to check the quality of these products. The

tests include flaring test, flattening test, third-party inspection, visual

inspection, chemical composition analysis and more. All the tests are done keeping

in mind the quality and performance that customers accept from these products.

In the end, these Incoloy 800 / 800H / 800HT Round Bars &

Wires are packed in waterproof quality of packaging material

helping avoid rust and damages.

Incoloy 800/800H/800HT Round Bars Specifications

Specification : ASTM B425 / ASME SB425

Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI

Length : 100 mm To 3000 mm Long & Above

Size : 5 mm To 500 mm

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc

Incoloy 800/800H/800HT Wires Specifications

Specifications : ASTM B425 ASME SB425

Dimensions : ANSI/AWCI – 01 -1992 and ASTM E 2016-11 and RRW 360

Length : 100 mm TO 6250 mm

Diameter Range : 10 mm To 100 mm

Specialize : Filler Wire, Coil Wire

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN | OR | AFNOR | BS | GOST |

| Incoloy 800 | 1.4876 | N08800 | NCF 800 | X10NiCrAlTi32-20 | XH32T | Z8NC32-21 | NA 15 | ЭИ670 |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | NCF 800H | X5NiCrAlTi31-20 | XH32T | Z8NC33-21 | NA 15(H) | ЭИ670 |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | NCF 800HT | X8NiCrAlTi32-21 | XH32T | – | NA 15(HT) | ЭИ670 |

| Incoloy | Fe | Si | Cr | Cu | Al | C | Mn | Ti | S |

| 800 | 39.5 min | 1.0 max | 19-23 | 0.75 max | 0.15-0.60 | 0.1 max | 1.5 max | 0.15-0.60 | 0.015 max |

| 800H | 39.5 min | 1.0 max | 19-23 | 0.75 max | 0.15-0.60 | 0.05-0.1 | 1.5 max | 0.15-0.60 | 0.015 max |

| 800HT | 39.5 min | 1.0 max | 19-23 | 0.75 max | 0.85-1.20 | 0.06-0.1 | 1.5 max | 0.25-0.6 | 0.015 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa –205 | 30 % |

Incoloy 800/800H/800HT Round Bars and Wires Application Industry

People Also Searched For Incoloy 800/800H/800HT Round Bars and Wires

incoloy 1.4859 round bar, incoloy uns N08800 filler wires, incoloy 800 welding wire manufacturers in mumbai, incoloy 800 round bars suppliers, incoloy 800 wire manufacturer in delhi, incoloy 800ht round bars and wires manufacturers, 800ht incoloy Alloy bright bar, incoloy 800 round bars exporters, incoloy 800 filler wire, incoloy 800h wire Dealers, incoloy alloy 800h square bar manufacturing process, incoloy 800ht square bar, A Wide Range Of the Best Quality incoloy alloy 800h/800ht forged round bars manufacturers in india, incoloy 800 round wires suppliers, incoloy alloy 800 wires manufacturers, incoloy 800h wires manufacturer in mumbai, incoloy 800 round bars manufacturers, incoloy uns N08810 round bar, incoloy 1.4876 wire bobbin, incoloy 800h rods suppliers, incoloy alloy 800/800h round bar and wire distributors, incoloy 800 wires manufacturers, incoloy 800ht wire price per kg, incoloy alloy 800 welding rod / welding wire manufacturers, incoloy 800 wires exporters, incoloy alloy 800ht cold finish round bar, incoloy 800ht rectangular bar stockholder, incoloy alloy 800h/800ht round rods.

Incoloy 800/800H/800HT Round Bars and Wires Packaging and Advantages

Types of Packaging:

– Bundles (hexagonal)

– Wooden Boxes

– Crates (steel/wooden)

– Packaging for Incoloy 800/800H/800HT Round Rod as per

customer’s requirements

Advantages :

– High Strength

– Resistant High Mechanical Stresses

– Resistant to High Temperature

– Good Formality

Incoloy 1.4876 Cold Finish Round Bar Suppliers | Incoloy Welding Wire Stockist | Incoloy UNS N08800 Welding Rods Exporters | Incoloy 800 Round Bars Manufacturers | Incoloy Alloy 800H Wires Price | Incoloy 800HT Round Rods distributors | ASTM B425 Incoloy Alloy Filler Wire | Incoloy Alloy 800 Forged Round Bar Ready Stock | Incoloy 800H/800HT Round Bar and Wires Exporter

If you’re looking for a trusted and reliable supplier of Incoloy 800/800H/800HT Round Bar and Wires then contact Shop no. 8B, Jai Siddhivinayak CHS., Ardeshir Dadi X Street, Mumbai - 400 004, Maharashtra, India