- Manufacturer Stockist & Supplier of : All Ferrous & Non Ferrous Metal

- Call us : +91 98927 02393

-

Email

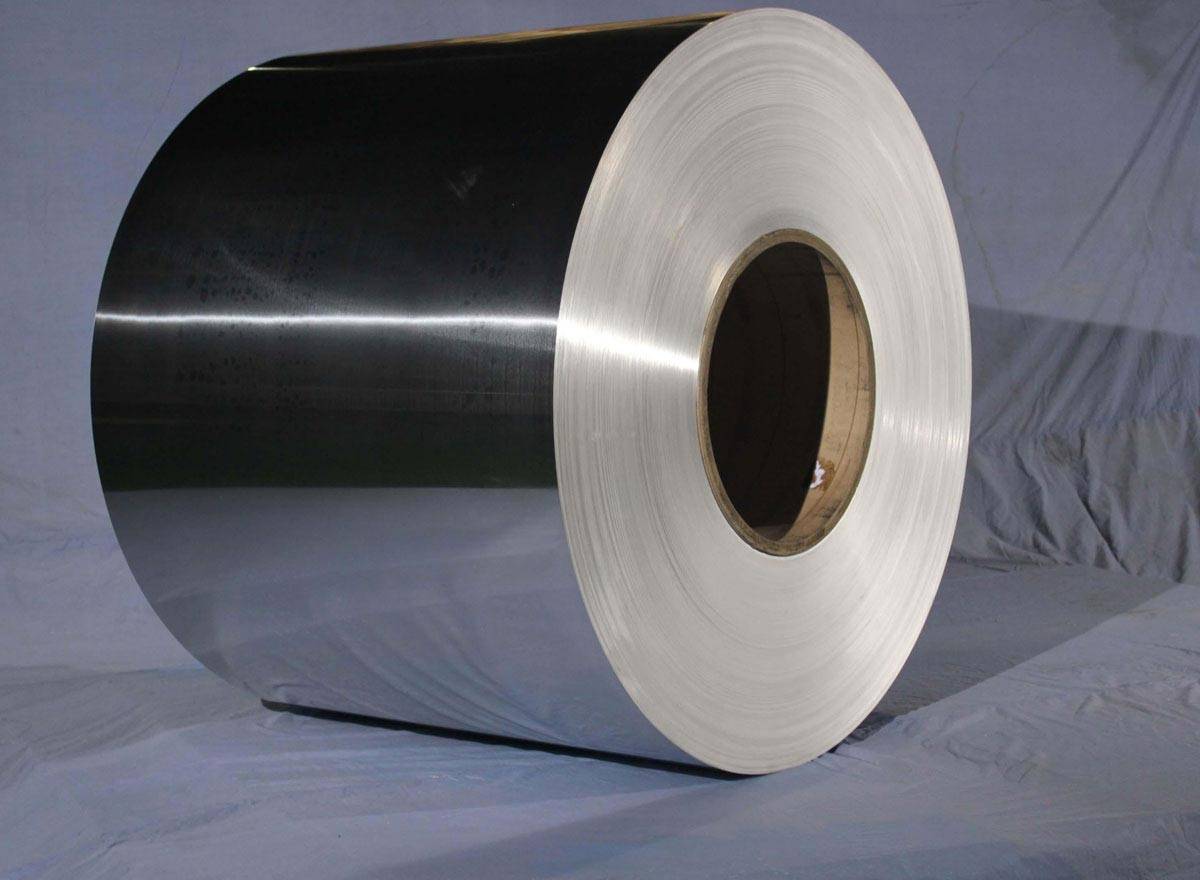

Aluminium 3003 Coil

Aluminium 3003 Coils

Panache Industries is a well-established manufacturer and supplier of 3003 aluminum coils, serving clients across India and overseas. Operating from Mumbai, we offer a comprehensive range of aluminum alloy coils tailored for use in construction, automotive, HVAC, and general engineering applications. Our aluminum 3003 coils are produced in line with international standards like ASTM B209 and ASME SB-209, ensuring consistent quality, durability, and precision in every batch.

The 3003 aluminum coil, also referred to by its UNS A93003, is a manganese-alloyed aluminum product that offers better strength than pure aluminum (like 1100 grade) while retaining excellent workability. It is composed of 98.6% aluminum, 1.2% manganese, and traces of copper. This combination renders aluminum alloy 3003 coils optimal for welding, spinning, and deep drawing operations. It is not heat-treatable; however, it can be cold-worked to enhance its resilience. Depending on the desired hardness and ductility, the material is available in temper conditions such as H14, H16, H18, and H24. In addition to its exceptional resistance to corrosion, 3003 aluminum is also highly resistant to atmospheric and chemical corrosion, rendering it an ideal choice for use in severely exposed environments.

Buy 3003 Aluminium Coils, Aluminium 3003 Coil, Aluminum 3003 Coils Suppliers, Exporters, and Manufacturers in India.

We stock aluminum 3003 coils in a wide variety of thicknesses, widths, and finishes to suit different needs. Common sizes range from 0.2 mm to 6 mm in thickness and widths up to 1500 mm. Finishes include mill finish, PVC-coated, stucco-embossed, and color-coated variants. Whether you need soft aluminum coils for insulation or harder tempers for forming applications, we provide coils with dimensional accuracy, smooth surface quality, and full test certifications on request. Our aluminum 3003 coils are also available with added benefits like enhanced formability for intricate applications, ensuring the versatility needed in modern manufacturing.

The 3003 aluminum coil price varies based on size, finish, and quantity. Typically, you can anticipate a price range of 280 to 360 per kilogram, contingent upon the particulars and the quantity of orders. Our team also offers volume discounts for large orders, custom-cut lengths, and roll-up packaging. For the latest stock details, technical sheets, or to request a custom quote, please feel free to get in touch with us at sales@panacheind.com or call us at +91 98927 02393.

3003 Aluminum Coil Manufacturers, Aluminium 3003 Coils, 3003 Slitting Coils, Check Aluminium 3003 Properties, Aluminum 3003 Alloy (UNS A93003) Coils Manufacturer, Exporter in Mumbai.

Aluminium Alloy 3003 Coil

Aluminium DIN 3.0517 Coil, 3003 Aluminium Alloy Coils, UNS A93003 Coils, ASTM B209 Aluminium Alloy 3003 Coils, ASTM B209 Aluminium Alloy 3003 Coils, Aluminium Alloy 3003 Coils, Aluminium Alloy 3003 Slitting Coil, Aluminium 3003 Coils Suppliers, Aluminium UNS A93003 Coil, Aluminium Alloy 3003 Slitting Coils.

Aluminium 3003 Coils

Aluminium 3003 Slitting Coils, Aluminium 3003 Coil, Aluminium Alloy 3003 Coils Supplier, Aluminium 3003 Coils, Aluminium 3003 Coils, ASTM B209 Aluminium Alloy Coil Exporter, Aluminium UNS A93003 Coil Exporter, Aluminium 3003 Coils Manufacturers, 3003 Aluminium Alloy Coils, Aluminium 3003 Coil Supplier.

The industry packaging method:

The industry use efficient packaging methods in order to preserve the quality of coils until the destination. The Aluminium 3003 Coilsare packed in fumigation free wooden cases, crates or pallets.

Aluminium 3003 Coils Specifications

Standards : ASTM B209 / ASME SB209

Temper : O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851

Thickness : 0.2~300mm

Length : 500~10000mm

Width : 500~2500mm

Surface : Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc

Finish : Mill, Customer specific finish

| European Standard | OLD | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) |

| AW-AlCu4Mg1 | AU4G1 | 3.0517 | A93003 | AlCu4Mg | 3003 | AlCuMg2 |

| Al | Cr | Cu | Fe | Mg | Mn | Other Total | Si | Ti | Zn |

| Remainder | - | 0.05 to 0.20% | 0.7% | - | 1.0 to 1.5% | 0.15% | 0.6% | - | 0.10% |

| Properties | Metric | Imperial |

| Tensile strength | 130 MPa | 18855 psi |

| Yield strength | 125 MPa | 18130 psi |

| Shear strength | 83 MPa | 12039 psi |

| Fatigue strength | 55 MPa | 7977 psi |

| Elastic modulus | 70-80 GPa | 10153-11603 ksi |

| Poisson's ratio | 0.33 | 0.33 |

| Elongation | 10% | 10% |

| Hardness | 35 | 35 |

Aluminium 3003 Coils Application Industry

People Also Searched For Aluminium Alloy 3003 Coil

aluminium 3003 coils, aluminium alloy 3003 coil size, aluminium coil uses, al 3003 coil, aluminium coil price in india, aluminium 3003 coils suppliers, 3003 aluminum coils, aluminium alloy 3003 slitting coil, aluminium alloy 3003 coils price list india, aluminium coil hs code, aluminium din 3.0517 coils, al alloy 3003 coil, aluminium 3003 coils exporters, aluminium 3003 coils manufacturers, hindalco aluminium coil, aluminium alloy 3003 coils stockholders, aluminium coil ac, aluminium coil supplier in delhi, aa 3003 coils, aluminium wire coil exporter in mumbai, aluminium alloy 3003 coils, 3003 aluminium coil distributors, aluminum coil price per kg

Aluminium Alloy 3003 Coils Packaging and Advantages

Types of Packaging:

– Bundles (hexagonal)

– Wooden Boxes

– Crates (steel/wooden)

– Packaging for Aluminium 3003 Coil as per customer’s

requirements

Advantages :

– High Strength

– Resistant High Mechanical Stresses

– Resistant to High Temperature

– Good Formality

Aluminium Alloy 3003 Coil Price | Aluminium Alloy 3003 Coils Distributors | Aluminium Alloy 3003 Coil | Aluminium Alloy 3003 Coils Stock | Aluminium Coils Suppliers | Aluminium Alloy 3003 Coil Supplier | Aluminium UNS A93003 Slit Coils Exporters | Aluminium Din 3.0517 Slitting Coil Manufacturers | Aluminium 3003 Coil Exporter

If you’re looking for a trusted and reliable supplier of Aluminium 3003 Coils then contact Shop no. 8B, Jai Siddhivinayak CHS., Ardeshir Dadi X Street, Mumbai - 400 004, Maharashtra, India