- Manufacturer Stockist & Supplier of : All Ferrous & Non Ferrous Metal

- Call us : +91 98927 02393

-

Email

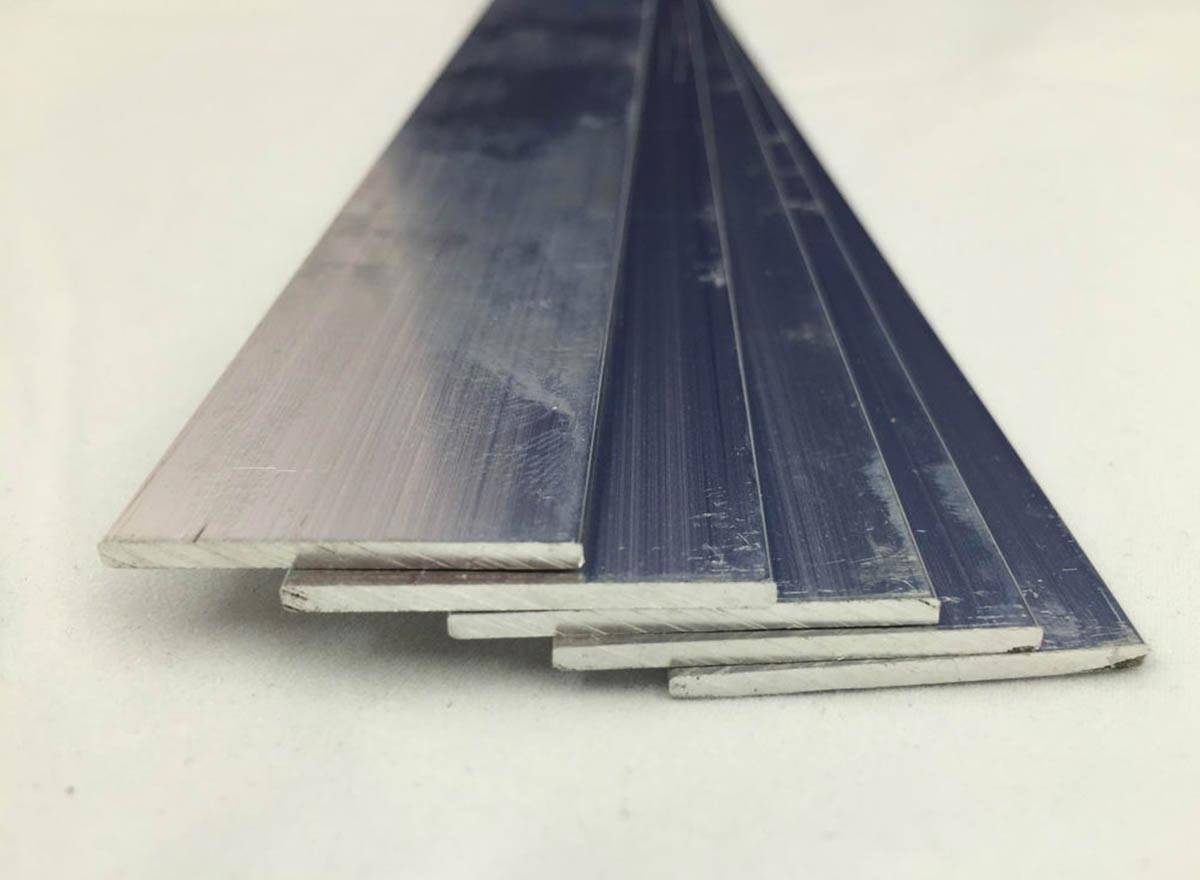

Aluminium 1050 Flat Bars

Aluminium 1050 Flat Bars

Aluminium 1050 Cold Rolled Flat Bars, ASTM B221 Aluminium 1050 Flat Bars Manufacturer, Aluminium 1050 Flat Rods, Aluminium Alloy 1050 Flat Bars Dealer in Mumbai, Aluminium 1050 Flat Bars Exporter, Aluminium 3.0255 Flat Bars, Aluminium 1050 Flat Bar, Aluminium Alloy 1050 Flat Bar Manufacturer in Mumbai.

Aluminium Grade 1050 is the most common grade though

it has the lowest strength as compared to other

commercial grades of aluminium. Due to its extremely

ductile nature, it fits into applications that require

forming and bending ability it can be easily formed

into a desired shape as requested by the application.

Also, the reflective or shine surface of the material

grade helps it to work as reflectors due to its highly

glossy surface. Corrosion resistance of the aluminium

grade is unbeatable as Aluminium 1050 Flat Bars

consists up to 99.5% pure aluminium thus can be used

in chemical as well as other open applications.

Aluminium Flat Bars have the following features to

offer such as excellent features, reliable surface,

precise dimension and many more. The main reason

behind the ultimate demand in the market place for

these grade products is due to its excellent

resistance to corrosion, in atmospheric as well as

marine applications.

Some of the mechanical and physical properties of the

Aluminium 1050 Flat Bars

are its tensile strength, lower hardness, elongation,

thermal conductivity, electrical resistivity and many

more. When it comes to the fabrication of this alloy then

due to its soft structure, it is not suited for machinery

application. Preferably, laser cutting is applied for the

processing of this alloy.

Quality assurance with the application of

tests:

Various test namely PMI test, corrosion resistance test,

macro test, micro test, intergranular corrosion test,

flaring test, hardness test, Spectro analysis test, and

many more are performed. Panache Industries makes sure

that all the tests are performed under the strict

supervision of the quality inspectors to ensure that the

Aluminium 1050 Flat Bars are manufactured as per the

international design standards.

DIN 3.0255 Flat Bars Supplier, Aluminium 1050 Hot Rolled Flat Bars, Buy Comprehensive Variety of Aluminium 1050 Flat Bars, UNS A91050 Hot Finish Flat Bars, ASTM B221 Aluminium 1050 Cold Drawn Flat Rod, Aluminium 1050 Flat Bars Manufacturer in India.

Aluminium 1050 Flat Bar

Aluminium 1050 Cold Drawn Flat Bars, Aluminium 1050 Hot Rolled Flat Bars, Aluminium 1050 Flat Bar, Aluminium 1050 Industrial Flat Rods, Aluminium 1050 Cold Rolled Flat Bars.

Al 1050 Industrial Flat Bar

Aluminium 1050 Flat Rods, Aluminium 1050 Cold Rolled Flat Rods, Aluminium Alloy UNS A91050 Flat Bars, Alloy Grade 1050 Flat Bar, Aluminium 1050 Industrial Flat Bars.

Packing and documentation:

Necessary documents such as fumigation certification, QAP

reports, packaging list, commercial invoice, material test

reports, guarantee letter, material traceability reports,

and many others are provided by the industry to its

clients. To avoid the Aluminium 1050 Flat Bars from

scratches while cutting, processing or shipping flat bars

are coated with PVC.

Furthermore, Panache Industries provides product range in

customized form depending on the application and

requirements of the clients.

Aluminium 1050 Flat Bar Specifications

Specification : ASTM B 221 ASME SB 221, B211, B565, B316 1100, AMS 4102

Standard : ASTM, BS and all International Standards

Temper : O, H12, H14, H16, H18, H22, H24, H26, H32, H112

Length : 100 mm To 3000 mm Long & Above

Size : 5 mm To 500 mm

Al 1050 Industrial Flat Bars, Aluminium 1050 Customized Flat Bars, Aluminium 1050 Flat Rods, Aluminum Alloy 3.0255 Flat Bars, 1050 Aluminium Flat Bars, ASTM B221 Al 1050 Flat Bars, Aluminum 1050 Flat Rod, Aluminum Alloy A91050 Flat Rod, UNS A91050 Flat Bars, Aluminum 1050 Flat Bar, Aluminium 99.5 Alloy 1050 Flat Bars

| STANDARD | UNS | WERKSTOFF NR. |

| Aluminium 1050 | A91050 | 3.0255 |

| Aluminium 1050 | Fe | Si | Mg | Mn | Cu | Zn | Ti | Al |

| 0.15 - 0.25 | 0.10 - 0.20 | 0.01 - 0.03 | 0.01 - 0.03 | 0.01 - 0.05 | 0.01 - 0.03 | 0.020 - 0.030 | 99.50 |

| Mechanical Properties - Al 1050 | ||||||

| Alloy | Temper | UTS(Mpa) | % Elongation | |||

| Min | Max | 0.5 mm -0.8 mm | 0.81 mm - 1.30 mm | 1.30 mm - above | ||

| 1050 | O | 55 | 75 | 25 | 25 | 30 |

| H12 | 75 | 110 | 6 | 6 | 7 | |

| H14 | 90 | 120 | 5 | 5 | 6 | |

| H16 | 95 | 130 | 4 | 4 | 4 | |

| H18 | 130 | --- | 3 | 3 | 3 | |

Density : 2.7 g/cm³

Melting point : 660.3 °C

Proof Stress : 85 Min MPa

Tensile Strength : 105 - 145 MPa

Aluminium 1050 Flat Bars Application Industry

People Also Searched For Aluminium Alloy 1050 Flat Bars

aluminium 1050 flat bars manufacturer in delhi, aluminium 1050 flat bar manufacturer in mumbai, aluminium 1050 hot drawn flat bar, aluminium 1050 flat bars manufacturers in mumbai, aluminium uns a91050 flat bar, aluminium 3.0255 flat rod, aluminium alloy 1050 flat bar distributors, aluminium 1050 flat bar Dealers, aluminium alloy 1050 flat bars manufacturing process, aluminium 1050 cold rolled flat bars manufacturers, aluminium 1050 hot rolled flat bar, al 1050 flat rods, aluminium 1050 flat rod stockholder, aluminium alloy din 3.0255 flat bars, al 1050 flat rod, aluminium uns a91050 flat bars, al 1050 flat bars suppliers, aluminium alloy 1050 flat bar manufacturers, a wide range of the best quality aluminium alloy 1050 flat bars, aluminium alloy cold drawn flat bar.

Aluminium 1050 Flat Bars Packaging and Advantages

Types of Packaging:

– Bundles (hexagonal)

– Wooden Boxes

– Crates (steel/wooden)

– Packaging for Aluminium Alloy 1050 Flat Bars as

per customer’s requirements

Advantages :

– High Strength

– Resistant High Mechanical Stresses

– Resistant to High Temperature

– Good Formality

Aluminium 3.0255 Flat Bars Suppliers | Aluminum Flat Bars Stockist | Aluminium UNS A91050 Flat Bars Exporters | Aluminium 1050 Flat Bars Manufacturers | Aluminium Alloy 1050 Flat Bars Price | Aluminium 1050 Flat Bars distributors | ASTM B221 Aluminium Alloy Flat Bars | Aluminium Alloy 1050 Flat Bars Ready Stock | Aluminium 1050 Flat Bars Exporter

If you’re looking for a trusted and reliable supplier of Aluminium 1050 Flat Bars then contact Shop no. 8B, Jai Siddhivinayak CHS., Ardeshir Dadi X Street, Mumbai - 400 004, Maharashtra, India