- Manufacturer Stockist & Supplier of : All Ferrous & Non Ferrous Metal

- Call us : +91 98927 02393

-

Email

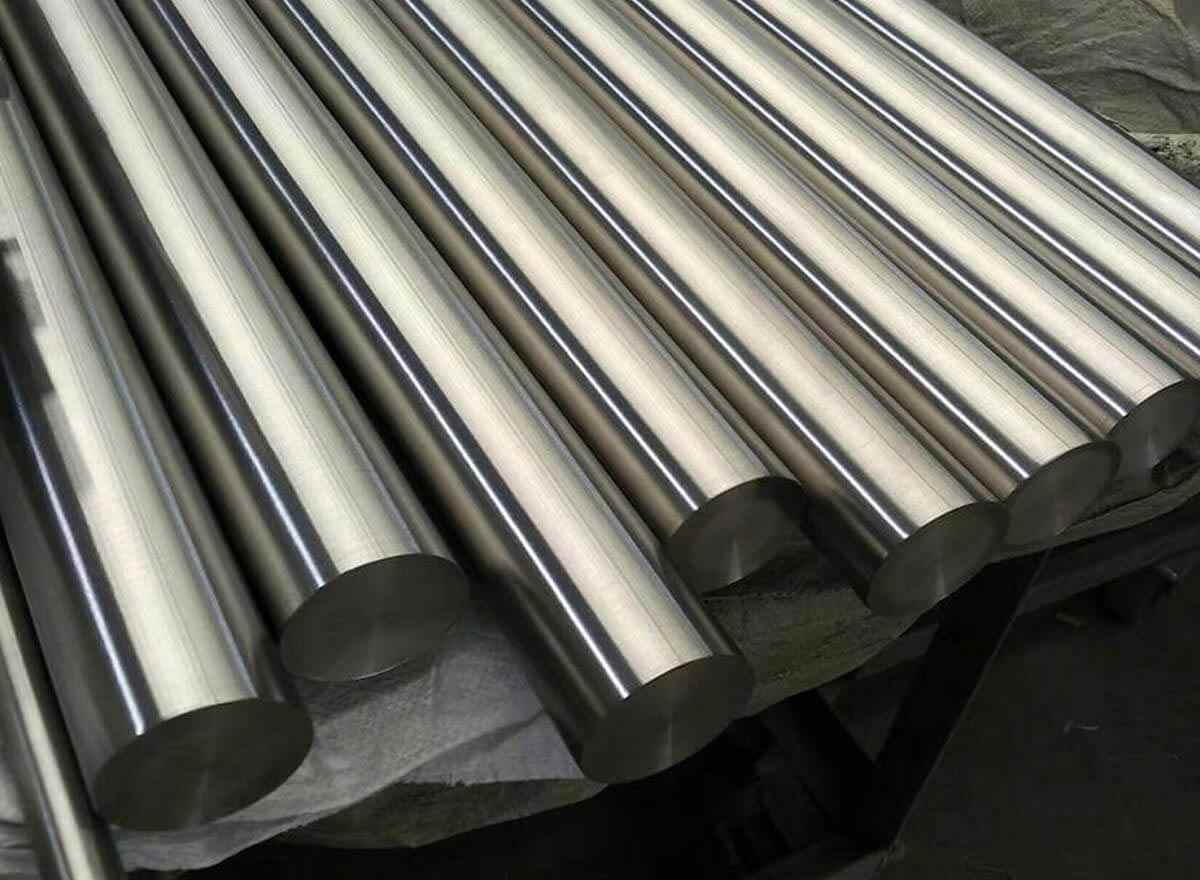

SMO 254 Round Bars and Wires

SMO 254 Round Bars and Wires

SMO 254 Flux Cored Wires Exporter, Alloy 1.4547 Round Bars, ASTM A276 SMO 254 Welding Rod / Welding Wire Manufacturer, SMO® 254 Rectangular Bar, SMO 254 Wires Manufacturers, 6 MOLY Bright Wires, SMO 254 Round Bar and Wire, SMO 254 Rods Suppliers, SMO 254 Cold Heading Wires Dealer in Mumbai, SMO 254 Bright Bar Manufacturer in Mumbai.

Panache Industries manufacture, produce and export an extensive range of

improved SMO

254 Round Bars & Wires. We specialize in quick

manufacturing and processing of products to meet customers’ most

demanding bars and wires requirements. We stock them in various

specifications, standards, designations, grades, and dimensions so

customers can get their products instantly. There is increased demand

for these bars and wires due to its attractive attributes.

Corrosion resistance:

SMO 254 Round Bars & Wires possess excellent resistance to general

corrosion. It has resistive to stress corrosion cracking (SCC). It is

resistive to pitting corrosion and crevice corrosion. It has similar

resistance to seawater conditions. It is an austenitic SS grade with

molybdenum content and widely utilized SS grade. It has excellent

resistance to high concentrated halide environments. It has resistance

to the crevice and has low magnetic properties. It has great impact

strength and ductility at extreme sub-zero temperatures.

Quality norms:

We implement stringent quality systems in our all production levels. The overall

product range is processed from various quality tests that ensure product

reliability and functionality in adverse environments. the tests followed by us

are crushing test, mechanical test, buckling test, hardness test, tensile test,

positive material test, micro and macro test, chemical test/ spectro analysis,

intergranular corrosion test, flaring test, destructive test, non destructive

test, ultrasonic test, radiographic test, pitting corrosion test and visual

inspection.

Buy Comprehensive Variety of Alloy DIN 1.4547 Forged Round Bars Supplier, SMO 254 Wire Rods, SMO 254 Round Bars Exporter, Alloy UNS S31254 Welding Wire Manufacturer, SMO 254 Round Bars Suppliers, SMO 254 Wires Suppliers, SMO 254 Rods Exporters, SMO 254 Rods Manufacturers, Alloy 254 Rectangular Bar, ASTM B473 SMO® 254 Filler Wires Manufacturer in India.

SMO 254 Wires

SMO 254 Fine Wires, 6 MOLY Wire, SMO 254 Wire Rod, SMO 254 Spring Wire, Alloy 254 Filler Wires, SMO 254 Rods Manufacturers, SMO 254 Wires Exporters, SMO 254 Flux Cored Wires, Alloy DIN 1.4547 Welding Rod / Welding Wire, SMO 254 Coarse Wires, 6MO Filler Wires, SMO® 254 Wires.

6 MOLY Round Bars

6 MOLY Round Bar and Rod, SMO 254 Round Rod, SMO 254 Round Bar, SMO 254 Threaded Bar, SMO 254 Rods Exporters, SMO 254 Round Bars, Alloy UNS S31254 Bright Bar, SMO 254 Round Bars Exporters, SMO® 254 Forged Round Bar, SMO 254 Rods Suppliers, Alloy 254 Round Bars, 6MO Welding Rod.

Documentations:

We provide some documents along with products as a quality offered by us. Also,

we attach some manuals so customers can use the offered products efficiently.

The reports are

Product invoice, specification guide, incorporate chemical composition, hardness

details after heat treatment welding guide, attested certificate by third

parties, fumigation certificates, packaging details, NABL test report, and MTC

report as per EN 10204 3.1 or 3.2.

Other reports are Certificate origin by legalized embassy, raw material test

report, mill test report, quality assurance plan, heat treatment charts,

stamping details, and guarantee letter.

We provide SMO 254 Round Bars & Wires in standard packing to ensure damage free

shipping. Generally, these are packed in custom packing of wooden boxes, crates,

and pallets.

SMO 254 Round Bars Specifications

Specification : ASTM A276 / ASME SA276

Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI

Length : 100 mm To 3000 mm Long & Above

Size : 7 mm To 500 mm

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Surface : Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Hairline

SMO 254 Wires Specifications

Specifications : ASTM B473 ASME SB473

Dimensions : ANSI/AWCI – 01 -1992 and ASTM E 2016-11 and RRW 360

Length : 100 mm TO 6000 mm

Diameter Range : 10 mm To 100 mm

Specialize : Filler Wire, Coil Wire, Electrode Wire, Welding Wire.

| STANDARD | UNS | WERKSTOFF NR. | EN |

| 254 SMO® | S31254 | 1.4547 | X1CrNiMoCuN20-18-7 |

| Grade | C | Ni | Si | N | S | Mn | P | Cr | Ce | Fe | |

| SS 254 SMO | min. | - | 17.5 | - | 0.18 | - | - | - | 19.5 | 0.03 | Balance |

| max. | 0.02 | 18.5 | 0.08 | 0.22 | 0.01 | 1.00 | 0.03 | 20.5 | 0.08 | ||

| Grade | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (MPa) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 254 SMO | 650 | 35 | 300 | 50 | 270 |

SMO 254 Round Bars and Wires Application Industry

People Also Searched For SMO 254 Round Bars and Wires

smo 254 wire manufacturer in delhi, 254 alloy bright bar, smo 254 rectangular bar stockholder, smo 254 round bars and wires manufacturers, alloy 254 square bar manufacturing process, 6 moly round rods, smo 254 round bars exporters, smo 254 filler wire, smo 254 wire dealers, smo 254 welding wire manufacturers in mumbai, smo 254 round bars manufacturers, smo 254 wires suppliers, smo 254 rods manufacturers, 6 moly cold finish round bar, 254 smo® welding rod / welding wire manufacturers, smo 254 round bars suppliers, smo 254 wire price per kg, alloy 254 round bar and wire distributors, alloy uns s31254 filler wires, smo 254 wires manufacturers, alloy 1.4547 round bar, 6 moly wires manufacturers, a wide range of the best quality smo® 254 forged round bars manufacturers in india, smo 254 wires exporters, alloy 1.4547 wire bobbin, smo 254 rods exporters, smo 254 square bar, smo 254 rods suppliers, smo 254 wires manufacturer in mumbai, alloy uns s31254 round bar.

SMO 254 Round Bars and Wires Packaging and Advantages

Types of Packaging:

– Bundles (hexagonal)

– Wooden Boxes

– Crates (steel/wooden)

– Packaging for SMO 254 Round Rod as per customer’s

requirements

Advantages :

– High Strength

– Resistant High Mechanical Stresses

– Resistant to High Temperature

– Good Formality

SMO 254 Round Bars Manufacturers | Alloy 254 Wires Price | SMO 254 Round Rods distributors | ASTM B473 SMO 254 Filler Wire | SMO® 254 Forged Round Bar Ready Stock | Alloy 1.4547 Cold Finish Round Bar Suppliers | 6 MOLY Welding Wire Stockist | Alloy UNS S31254 Welding Rods Exporters | SMO 254 Round Bar and Wires Exporter

If you’re looking for a trusted and reliable supplier of SMO 254 Round Bar and Wires then contact Shop no. 8B, Jai Siddhivinayak CHS., Ardeshir Dadi X Street, Mumbai - 400 004, Maharashtra, India